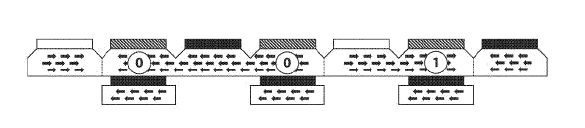

Qualcomm is developing perpendicular STT-MRAM

Back in June 2010 We learned that Qualcomm is developing MRAM technologies. Now Qualcomm's QTI Advanced Memory Team posted a job opening that details a mobile STT-MRAM lead technologist - that will lead the development of next-generation mobile SOC memory subsystems that integrate Perpendicular STT-MRAM.

Back in June 2010 We learned that Qualcomm is developing MRAM technologies. Now Qualcomm's QTI Advanced Memory Team posted a job opening that details a mobile STT-MRAM lead technologist - that will lead the development of next-generation mobile SOC memory subsystems that integrate Perpendicular STT-MRAM.