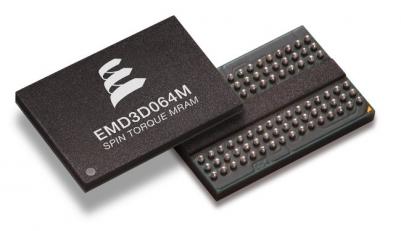

Everspin started to produce MRAM chips with a Quad-SPI interface

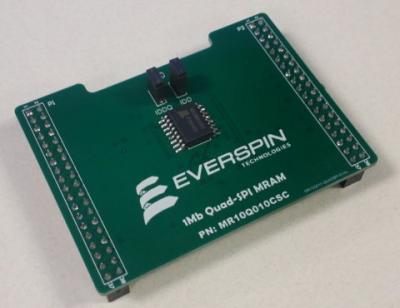

Everspin announced a new MRAM chip, the MR10Q010 - a 1Mb QSPI MRAM. Everspin says that at 104 Mhz, this is features the fastest non-volatile write speeds in the industry. The MR10Q010 is now available in both SOIC and BGA packages.

Everspin says that the new chip is suitable for applications such as enterprise RAID controllers - that can use the MR10Q010 as a journal memory that records continuously updated system metadata.