Tower to make MRAM chips for Crocus, also invests 1.25M$

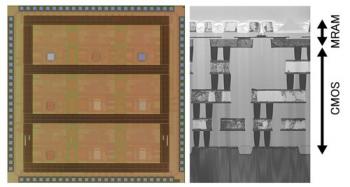

Crocus announced today that Israeli Tower fab will manufacture their next-gen MRAM chips. Tower has an exclusive agreement to make the MRAM chips at their 200mm Fab2 facility. Tower has also invested 1.25$ at Crocus.

Crocus announced today that Israeli Tower fab will manufacture their next-gen MRAM chips. Tower has an exclusive agreement to make the MRAM chips at their 200mm Fab2 facility. Tower has also invested 1.25$ at Crocus.

Crocus aims to start making the chips towards the end of 2009.

Crocus' basic technology is based on Field-Induced MRAM (Toggle MRAM), which is in some ways similar to Everspin's technology (or 1st generation MRAM). Historically, Field-Induced MRAM is very hard to scale, and has stability and retention problems. Crocus aims to solve all this using a thermally activated magnetic latch. They call their technology Thermally Assisted Switching or TAS. Basically this means that the latch helps the cell retain the memory value very well. It can also scale quite well. We have talked to Crocus' CEO, back in March 2009.