This is a sponsored post by Integral Solutions Int'l

MRAM is likely to be the most promising next-generation non-volatile memory technology today. Toggle MRAM and STT-MRAM are already entering the market, gaining market share in many applications. Next-generation MRAM technologies, such as SOT-MRAM could enable the replacement of even the fastest SRAM applications, with higher densities.

Source: Coughlin Associates, 2019

Source: Coughlin Associates, 2019

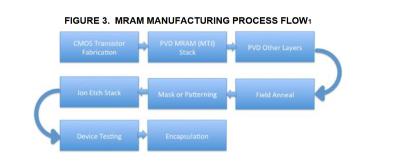

The MRAM production process has many stages, as device architecture is relatively complex, with a magnetic cell (frontplane) fabricated on top of a CMOS backplane. (use Figure 2 or Figure 3 from Coughlin). Measurement and characterization of devices are highly important, and the production of MRAM memories depend on measurement tools are are specialized for MRAM and STT-MRAM measurements.

Integral Solutions Inc (ISI) makes Quasi-Static testers for MRAM development and production. In fact, ISI was the first company to make wafer level testers for the MRAM industry and probably has the largest installed base of STT-MRAM wafer level testers. The company's longtime experience in the HDD head industry gives them unsurpassed experience in MTJ testing that they bring to the emerging MRAM testing industry.

Tom Coughlin, from Coughlin Associates, has written a white paper that discusses the current MRAM market and the importance of specialized MRAM device testing and also details ISI's current tools for the industry in addition to the company's future roadmap. Read the white paper here.