Leading the Charge in MRAM: An Interview with Everspin's CEO

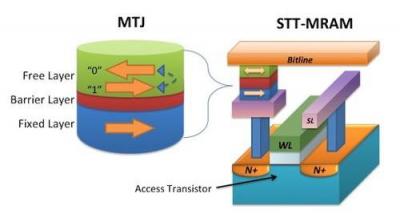

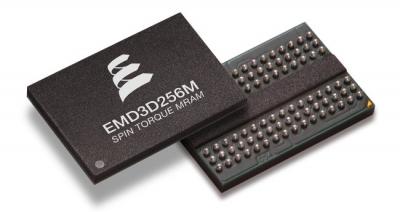

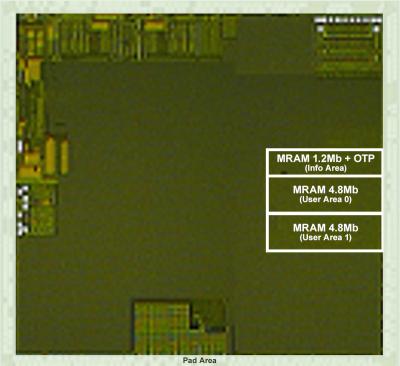

Everspin Technologies is at the forefront of the MRAM industry, with a product range that spans Toggle MRAM and STT-MRAM, embedded MRAM IP, more. The company's president and CEO, Sanjeev Aggarwal, was kind enough to answer a few questions we had about the company, it's recent announcements and its future roadmap.

Thank you for your time Sanjeev, we appreciate it. A few days ago, Everspin announced it had received a strategic $14.55 million 2.5-year DoD project to provide continued and stable manufacturing services. Can you share more info? How will that money be allocated, and how will you ensure stable support?

Everspin has partnered with the DoD on various projects to deploy our MRAM technology and fab MRAM products for Defense Industrial Base customers in Chandler, Arizona. The award money will be used to strength the US MRAM manufacturing supply chain. Everspin will look at its supply chain and mitigate any risks identified. This can include second-sourcing gases and chemicals as well as upgrading processes.