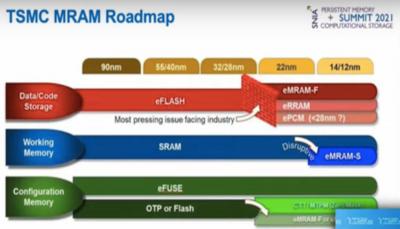

ITRI and TSMC announce advances in SOT-MRAM development

In 2022, Taiwan's Industrial Technology Research Institute (ITRI) announced an agreement with Taiwan Semiconductor Manufacturing Company (TSMC) to collaborate on SOT-MRAM R&D. ITRI and TSMC now announced that they have developed SOT-MRAM array chips that boasts a power consumption of merely one percent of a comparable STT-MRAM device.

ITRI and TSMC published a new research paper that was presented at the 2023 IEE International Electron Devices Meeting (IEDM 2023). ITRI explains that the new unit cell achieves simultaneous low power consumption and high-speed operation, reaching speeds as rapid as 10 nanoseconds. And its overall computing performance can be further enhanced when integrated with computing in memory circuit design.