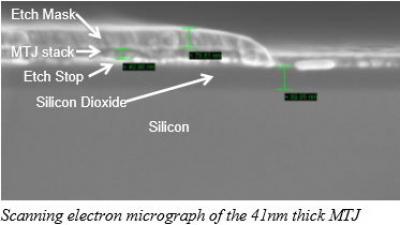

Researcher from Cornell's NanoScale Science and Technology Facility (CNF), in collaboration with Oxford Instruments Plasma Technology (OIPT) developed a new etching process targeted specifically for MRAM device fabrication.

The etching of the MTJ stack is a challenging step in MRAM fabrication, because the magnetic materials do not easily react to etching agents, and so manufactures usually use purely physical ion milling processes - which results in low etch rates, low selectivity and damage to the device structure itself.

The researchers managed to develop a new etching process that is achieved using plasmas formed from methanol and argon.

Source:

Posted: Mar 06,2016 by Ron Mertens